As a leading plastic injection mold manufacturer, GV MOLD specializes in custom plastic injection molds and injection molding.

We serve a wide range of industries, including home appliances and automotive, delivering high-quality, precision components for electronic goods, industrial applications, and housewares. Our advanced molding techniques ensure reliable, top-quality products.Engineering Services

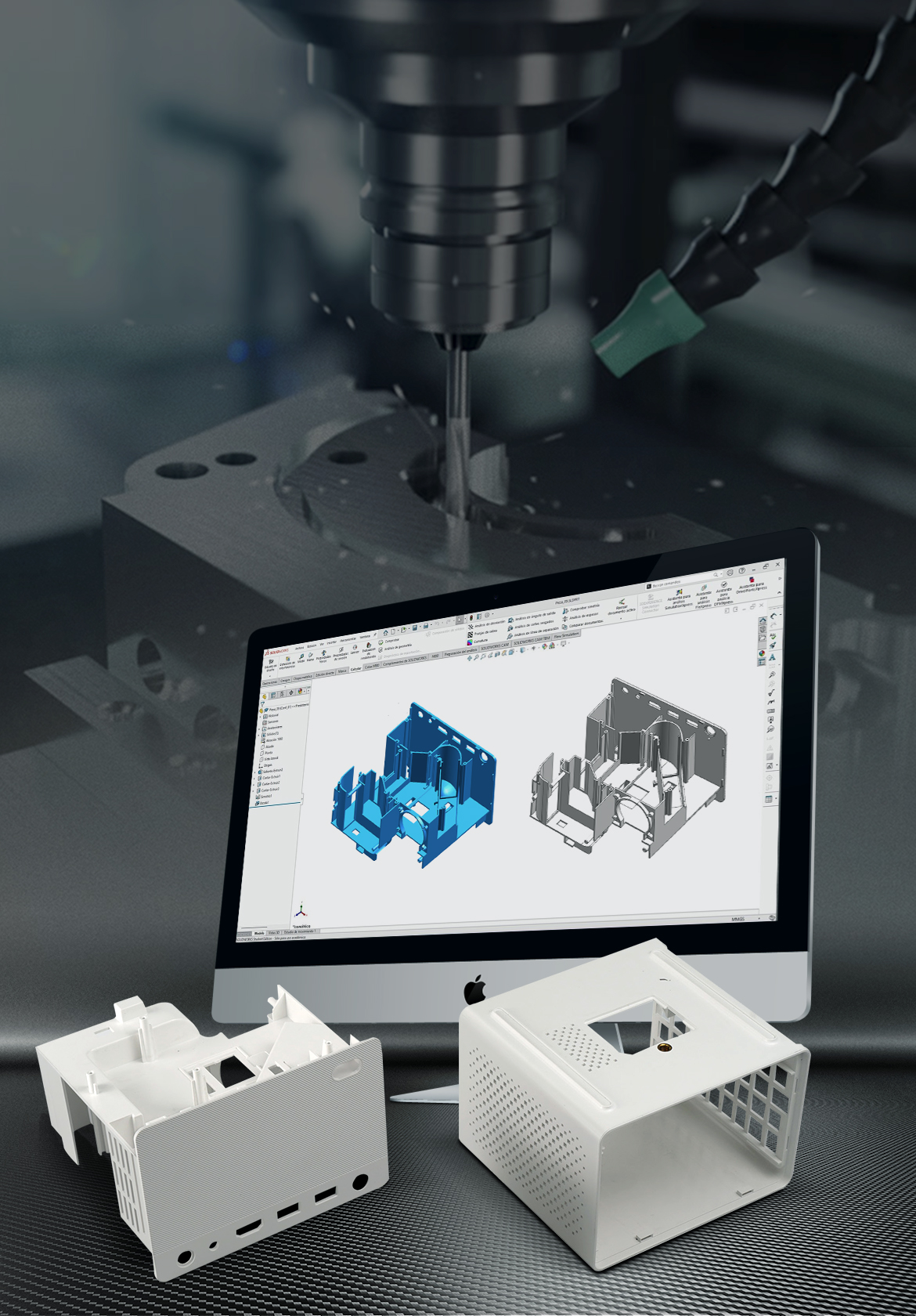

Expert Product Design & Iteration Services for Plastic Products

The design phase marks a pivotal and essential step in the product development journey. At GV MOLD, our team of skilled designers and engineers is dedicated to providing expert design support.

As a professional custom plastic injection molding manufacturer in China, GV MOLD specializes in creating innovative plastic products and components from the ground up, utilizing original blueprints to guide our process. Should you need to refine your product through iteration, our expertise in reverse engineering allows us to construct precise 3D models, tailoring them for optimal manufacturing efficiency.

Professional team of designers and engineers.

Professional team of designers and engineers. Tailor-made for optimal manufacturing efficiency.

Tailor-made for optimal manufacturing efficiency.Tooling and Mold Building for Plastic Injection Molding

Plastic injection mold building is a specialized process that involves the creation of intricate metal molds used in plastic injection molding machines. These tooling and molds are designed to precision specifications to ensure that molten plastic is formed into desired shapes with high accuracy and repeatability. The process includes mold design, steel material selection, CNC machining, and assembly, which is crucial for manufacturing a wide range of plastic products.

Design, steel selection, CNC machining and assembly.

Design, steel selection, CNC machining and assembly.Essential Role of DFM and MF in Plastic Injection Molding

DFM (Design for Manufacturing) and MFA (Mold Flow Analysis) are essential for plastic injection molding to ensure the part can be produced efficiently. DFM optimizes the part design for the molding process, preventing issues like sink marks and warping. MF ensures the mold maintains structural integrity and precise part alignment during injection, reducing the risk of defects and ensuring consistent production. These steps streamline manufacturing, minimize rework, and enhance the overall productivity and profitability of the molding operation.

Reduce the risk of defects and ensure production consistency.

Reduce the risk of defects and ensure production consistency. Improved overall productivity and profitability of molding operations.

Improved overall productivity and profitability of molding operations.Optimal Material Selection for Plastic Molded Components

Plastic material selection for plastic parts should consider application requirements, such as strength, flexibility, temperature resistance, and chemical compatibility. Additionally, factors like wear resistance and electrical properties are vital.

The chosen material profoundly affects the part's functionality, cost, and sustainability, guiding the overall design and performance of the product.

Strength, flexibility, high temperature resistance and chemical compatibility.

Strength, flexibility, high temperature resistance and chemical compatibility.Enhancing Product Development through Early Supplier Involvement

Early Supplier Involvement (ESI) in product development integrates suppliers early in the design process, fostering collaboration and leveraging their expertise. This approach can reduce costs, improve product quality, and accelerate time-to-market by optimizing materials, processes, and design for manufacturability. ESI also enhances communication, allowing for better risk management and more informed decision-making, ultimately leading to more competitive and sustainable products.

Reduce costs and improve product quality.

Reduce costs and improve product quality. Create more competitive and sustainable products.

Create more competitive and sustainable products.Capabilities

GV MOLD turns ideas into commercial products, consistently ensuring top-tier quality and production efficiency.

Reduce development costs.

Reduce development costs. Quickly verify product functionality.

Quickly verify product functionality.

30 years of experience in injection mold design and mold manufacturing.

30 years of experience in injection mold design and mold manufacturing. 17 years of mold export experience.

17 years of mold export experience.

A range of tailor-made molding solutions.

A range of tailor-made molding solutions. Provide precision and high quality injection molding products.

Provide precision and high quality injection molding products.

Expertise to enhance the functionality and design of your components.

Expertise to enhance the functionality and design of your components.