no data

Why GV MOLD

(以下展示客户服务卖点,文字可保留,图片换为定制图或者是产品工厂相关),间距宽比网站窄一点,内容宽一点,以下内容一样)

二、Injection Molding Factory

Shanghai Shangke Intelligent Shade Technology Co., Ltd.: specializes in the production of outdoor pergola, zip screen, smart building exterior sunshade and other sunshade products.

◉ Global customization service

We provide Saw customization services worldwide, including appearance, size, color, etc.

Professional R&D and design teams continuously innovate products and strictly control quality.

16+ years of experience, fully understanding the customization needs of different applications.

Maximize profits with one-stop services from customization, labels, packaging, delivery, etc.

The professional team provides you with services such as design and installation tutorials.

三、产品/服务

Plastic Injection Molding Products/Our One-stop Low Volume Production Services

(分别放8张精密加工件/模具产品,4*2,不轮播,精密件可以使用不同工艺处理的名称/场景名称。模具名称使用对应场景的模具图和命名。)

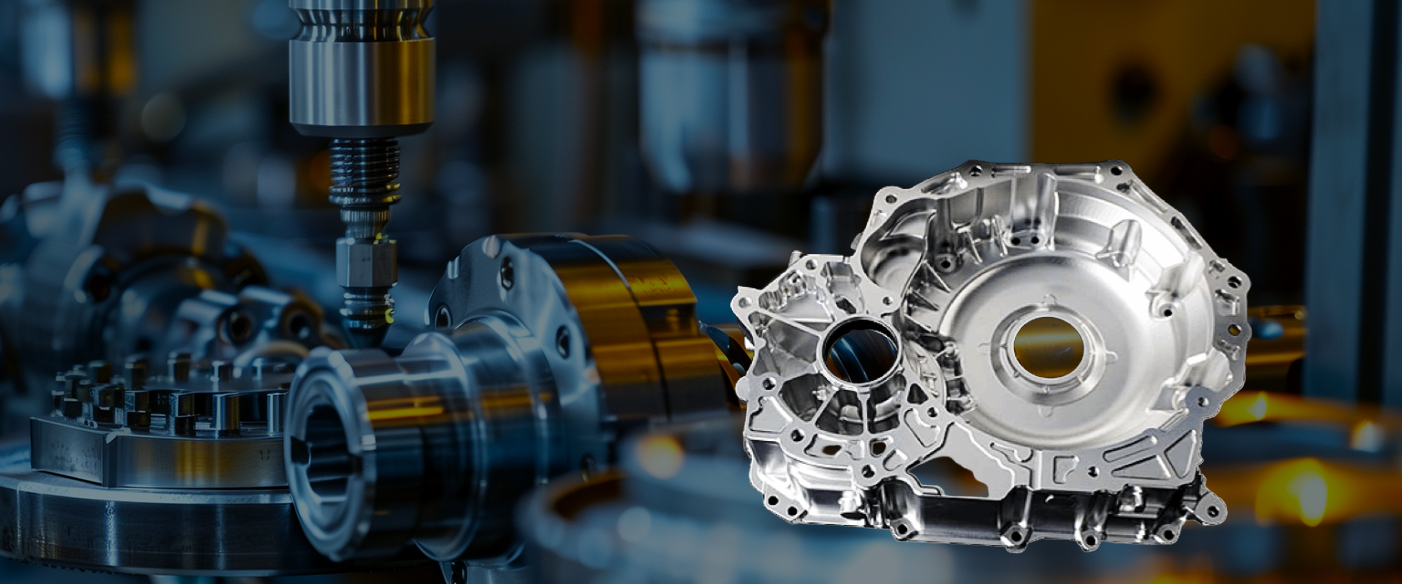

Our company specializes in plastic injection mold manufacturing and injection molding, catering to a broad spectrum of industries from home appliances to automotive. We also leverage cutting-edge material development and production methods to deliver reliable, high-quality components for electronic consumer goods, industrial applications, and housewares items.

mold

Our home appliance molds, characterized by their high precision, ensuring impeccable product quality. Built to last with durable materials, these molds withstand the rigors of mass production. Our designs accommodate complex shapes and functionalities, showcasing our commitment to innovation and compatibility with a wide range of appliance types. Experience the perfect blend of quality, reliability, and advanced technology in every mold.

no data

4、Our Technologies and Tool  (injection mold和plastic injection molding 分别放对应的技术和优势,比如快速模具,金属冲压,表面处理,塑料成型。模具的精准度,耐用度,性能标准、免费护理等,参考模具页面的卖点;塑料件的:小批量生产,精准公差0.01mm,DFM,MF,材料选择等。)

(injection mold和plastic injection molding 分别放对应的技术和优势,比如快速模具,金属冲压,表面处理,塑料成型。模具的精准度,耐用度,性能标准、免费护理等,参考模具页面的卖点;塑料件的:小批量生产,精准公差0.01mm,DFM,MF,材料选择等。)

(injection mold和plastic injection molding 分别放对应的技术和优势,比如快速模具,金属冲压,表面处理,塑料成型。模具的精准度,耐用度,性能标准、免费护理等,参考模具页面的卖点;塑料件的:小批量生产,精准公差0.01mm,DFM,MF,材料选择等。)

(injection mold和plastic injection molding 分别放对应的技术和优势,比如快速模具,金属冲压,表面处理,塑料成型。模具的精准度,耐用度,性能标准、免费护理等,参考模具页面的卖点;塑料件的:小批量生产,精准公差0.01mm,DFM,MF,材料选择等。)Our comprehensive capabilities allow us to offer a full range of services, from initial design to prototyping and all the way through to mass production, all under one roof. This integrated approach offers our clients several benefits, including cost and time efficiencies.

no data

With a fleet of 50 injection molding machines

With a fleet of 50 injection molding machines, we are equipped to handle a wide range of part sizes and complexity. Our machines are capable of producing anything from small, intricate components to large, robust plastic parts.

By consolidating all design, prototyping, tooling, and injection molding mass production processes within a single facility, Green Vitality streamlines the product development cycle. This significantly cuts down on lead times and production costs. Our vertically integrated approach ensures that every step of the process is closely monitored for quality and efficiency, delivering a seamless and reliable service to our clients.

5、流程How We Bring Your Design Into Reality

(以下icon使用橘色)

We turn ideas into commercial products, consistently ensuring top-tier quality and production efficiency.

6、Application

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality Industry provides a wide range of product solutions for the manufacture of various plastic injection parts.

no data

XApplication

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality Industry provides a wide range of product solutions for the manufacture of various plastic injection parts.

no data

8、Our Advantages

Possesses an experienced and skilled design and manufacturing team with many years of experience in the mold industry, capable of addressing various complex design and manufacturing challenges.

no data

Partners

GV Mold Factory is at the forefront of injection molding technology, offering the most advanced and innovative solutions in the mold industry.

no data

9、Get in touch or visit us

Let's Talk About Your Mould Project Now.

Have a professional production and management team.

Design With More Intelligence, Speed, & Profitability

no data

Reduce development costs.

Reduce development costs.